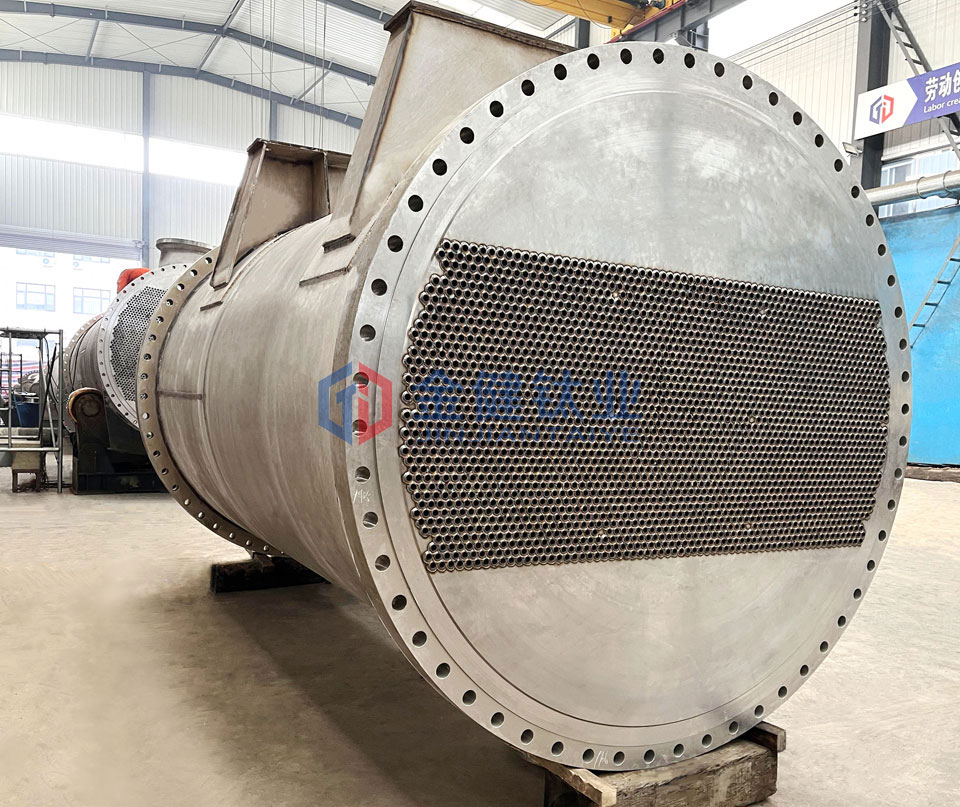

Heat Exchanger

Expansion surface of heat exchange tube: circumferential fins, longitudinal fins, plate fins

Rotating Flow Lift: Spiral Rib Rotating Link Twisted Tube shaped New Flow Device

Surface treatment: hydrophobic coating, anti-corrosion coating, porous coating, sintering

Rough surface: corrugated joints, internal waves, external threads,

transverse grooves, straight grooves, corrugated joints,

three-dimensional ribs

Single phase heat transfer enhancement can

be divided into internal flow and external flow, and can also be further

divided into laminar flow enhancement and turbulent flow enhancement.

The main mechanism for enhancing laminar and turbulent flow is to

increase the secondary heat transfer surface and disrupt the previously

unreinforced fluid velocity and temperature distribution fields.

Laminar flow enhancement: The heat transfer film coefficient of laminar

flow is relatively low, and the changes in fluid velocity and

temperature are distributed throughout the entire channel width. The

thermal resistance is not concentrated near the wall like turbulence,

and the enhancement effect of small-scale rough surfaces in laminar flow

is not significant; The usual reinforcement measures involve generating

vortices or creating turbulence.

Turbulence enhancement: During

turbulence inside the pipe, most of the thermal resistance is

concentrated in the low-speed zone near the wall where the fluid

velocity is approximately zero, that is, the laminar bottom layer. Any

rough surface or strengthening technique is used to disrupt laminar flow

in order to improve heat transfer. The inner flow layer thickness of

the d=25.4mm tube with Re=3000 is 0.0762mm.

Phase change heat

transfer enhancement: Condensation enhancement utilizes surface tension

to obtain a very thin condensation film thickness or quickly drain

condensate from the condensation surface. Droplet condensation has high

heat transfer efficiency and high heat flux density. Strengthening heat

transfer to reduce the thickness of the liquid film, in order to improve

heat transfer efficiency.

Special surface treatment involves

coating the surface with a layer of low surface energy material,

resulting in droplet like or droplet film coexistence condensation

The special surface geometry allows for faster drainage of condensate.